Protection and management of oil & gas assets has undergone a paradigm shift which is more dependent on the highest level of accuracy and reliability of the acquired data. Therefore, asset owners are inculcating paramount importance to the concept of “Asset Integrity”, especially in the energy sector.

Explore More

Pipeline Integrity Management Programs (PIMS), Corrosion Audits

Direct Assessment (DA) for Piggable and Non-Piggable Pipelines.

In-line inspection for Piggable and Non Piggable Pipelines

Spectrum XLI: State of the art surveys – Simultaneous, continuous and encrypted following surveys – GPS Mapping, Depth of Cover, CIPS (AC & DC), DCVG, ACVG, CAT/ACCA, Gas Leak Detection. Optional – Soil Resistivity and Pipe Wall Assessment (Large Standoff Magnetometry)

Pipeline Composite Repairs using Clock Spring | NRI, USA

Training: NACE (DA, PCIM, IC) / ASME (B31.8S)/ Customized

Our experts develop and implement “turnkey” pipeline integrity programs that address both the immediate maintenance...

Explore More

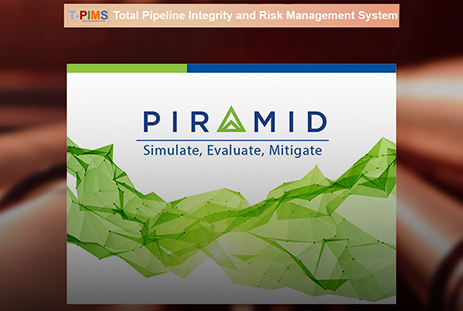

AE’s Total Pipeline Integrity Management Solutions (T-PIMS) is a comprehensive software...

Explore More

Utilize our automated field data collection systems and data management expertise to assess pipeline condition and prioritize remedial programs...

Explore More

In 2017, Allied Engineers introduced the eXternal Line Inspection (XLI in collaboration with PureHM) in India and Middle East region to provide...

Explore More

In-line inspection can be performed for piggable and “difficult to inspect”/ non-piggable pipelines. Onshore and Offshore trunk pipelines for most...

Explore More

AE has surveyed non-intrusively 100’s of pipelines for “live” gas leak detection and found ongoing gas leaks at several locations...

Explore More

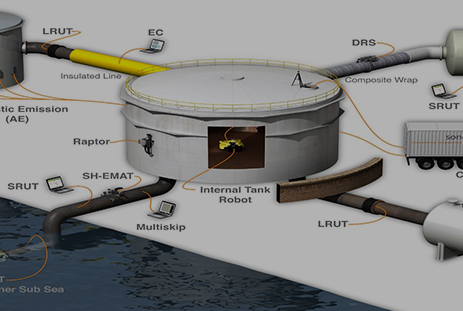

AE has been utilizing Long Range Ultrasonic (LRUT) Inspection for diameter 4” and up to help in many of its pipeline integrity program...

Explore More

The Clock Spring composite repair sleeve and reinforcement system is uniquely designed...

Explore More

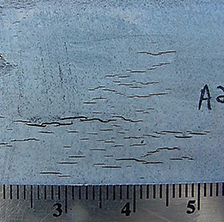

With more than 9,000 km of Stress Corrosion Cracking assessment experience by utilizing our...

Explore More

Proving a pipeline’s Fitness for Service, providing the safest operating pressure or a customised “pipeline management” plan for increasing...

Explore More

Allied Engineers have certified AMPP (NACE) and ASME Instructors providing training on pipeline integrity related courses globally...

Explore MoreAllied Engineers strives to demonstrate excellence in protecting the Health & Safety of people, Environment, and Property associated with its activities by maintaining

Explore More

Multi level checks are carried out with the aim to keep data totally error-free in order to maintain optimum levels of quality. They can be compiled as below:

Explore More

Our goal has been to provide complete custom designed integrity management services. This is achieved

by forming alliances with specialized technology providers (world leaders in their individual fields) to

provide the client with a “turnkey integrity solution under one single umbrella”.

C-FER Technologies and Allied Engineers are partnering to provide a Pipeline Integrity Management System (PIMS) to India’s Oil and Natural Gas Corporation (ONGC). The project brings together Allied Engineers’ pipeline integrity...

While his home in Houston was on the brink of flooding, Marcus McDonnell was half way around the globe in India; eating a Maharaja Mac! Marcus is a man of few words, so all he had to report was “I had an Indian Big Mac today… chicken instead of beef, jalapenos instead of pickle, orange curry sauce instead of white mystery sauce. LOL”

Since 2005 (3+ years) for the TPS and Kuwait Oil Company (KOC) ‘Total Pipeline Integrity Management Services (TPIMS)’ contract, Allied Engineers our approved Sub contractor have provided and continue to provide the following services for Tuboscope Pipeline Services (TPS), a National Oilwell Varco company.

"Allied Engineers provides ExMag with ongoing SCC Modelling and reporting services for our clientele in the North American pipeline market. These services include the following:

Case Study on Ultrasonic Intelligent Pigging for creating baseline and increasing production...

Explore More

Process Optimization & Efficiency: ‘Above-ground pipeline survey using Integrated Indirect...

Explore More

‘Case Study on Simultaneous Crack and Metal Loss Inspection’ by performing Ultrasonic...

Explore More

Managing Urban Infrastructure Crisis for maintaining integrity of oil and gas pipelines...

Explore More

Managing Urban Infrastructure Crisis for maintaining integrity of oil and gas pipelines...

Explore More

‘Integrity validation revealed severe Internal Corrosion on a Crude Oil Non-Piggable...

Explore More

‘Integrity validation revealed severe Internal Corrosion on a Crude Oil Non-Piggable...

Explore More

Offshore 48” Pipeline Successfully inspected through Internal Corrosion Direct Assessment...

Explore More

Protecting the Integrity of Fired Heaters by utilizing Advanced Intelligent Pigging Inspection...

Explore More

System Wide ECDA application advances integrity management of Kuwait Oil Company’s pipelines...

Explore More